Highlights

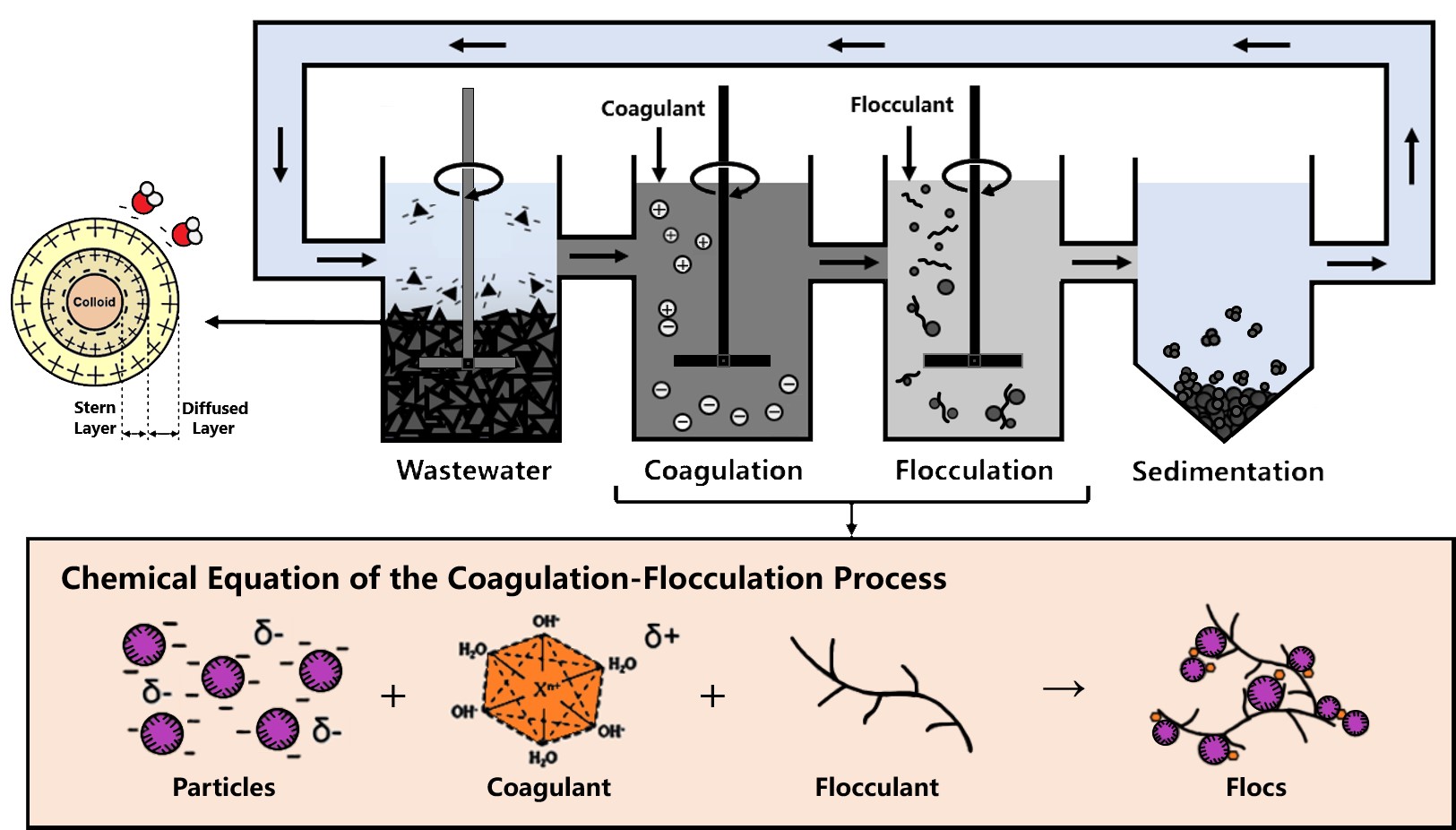

- • Coagulation-flocculation sedimentation fits pseudo-first-order reaction modeling

- • Changes in settlement efficiency result from coagulant choice and flocculant dosage

- • Suitable reagent combinations can effectively enlarge the microscale floc volume

- • The optimal sediment conditions for selected coal-washing wastewater are advanced

Abstract

Coal-washing wastewater is the residual produced by the coal industry, which may represent a high risk of serious environmental problems worldwide. However, prevailing coal-washing treatment processes are hardly ideal for achieving the goal of solid–liquid separation due to the wastewater’s extremely stable physicochemical properties. This research treats the coal-washing wastewater produced by a plant in Northeast China by means of the coagulation–flocculation process. The sedimentation ability of different coagulant choices and flocculant dosages is tested and analyzed through pseudo-first-order reaction kinetics. Scanning transmission electron microscopy is used to account for the settlement mechanism of flocs, which not only explains the characterized effect of coagulants and the flocculant but also demonstrates the advantage of using combined coagulates. Using the three-dimensional response surface method, an optimized treatment condition of 1.20 g m(FeCl3): m(CaO) = 1:3 mixed coagulants + 2.00 mL 0.13% polyacrylamide flocculant is proposed for 100 mL of selected wastewater. Additionally, the relationships between the optimal treatment conditions and the properties of wastewater obtained from X-ray energy-dispersive analysis are determined for future practical optimization needs.

Keywords Coagulant; Flocculant; Optimization modeling; Pseudo-first-order regression; Sedimentation mechanism

Publication International journal of Environmental Science and Technology